|

|

|

| |

Contactless glass level measuring |

|

|

| |

|

|

With contactless measurement registration for all types of glass

The innovative melt surface level measuring instrument, type:

SNG-PG-D97

is a further development of the measuring instruments manufactured by our company for more than 50 years and fulfils the high requirements expected today from a modern measuring system.

With the Melting Bath Level-Transmitter the changes of the level, respectively variations of a certain nominal height of the melt in glass or basalt melting ends and furnaces are measured.

A special probe is recording contactless all changes of the level.

|

|

|

| |

| |

Control mode on a melting bath with continuous mixed intermediate layer |

|

| |

|

|

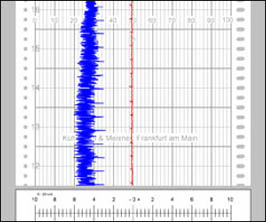

The adjacent excerpt from a recorder chart shows a typical control curve of a continuously controlled glass level on a regenerative heated melting end.

The red recorder curve represents the controlled level, measured with the KÜHNREICH & MEIXNER melt surface level measuring instrument SNG-PG-D 97. The small periodically occurring fluctuations to the left are caused by the drop of the furnace space temperature during the control change-over. The blue recorder curve shows the control signal which is given by the glass level controller to the filling machine - in this case to a vibrator channel. The size of this signal is according to the measured level deviation from the required set-point.

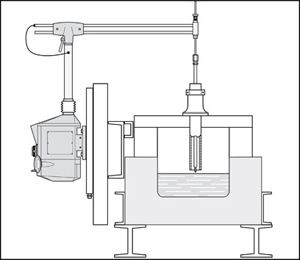

For the application of the non-cooled probe, the installation takes place at the feeder or at a specially pre-built measuring point on the melting bath. |

|

|

| |

| |

Level measurement with uncooled measuring |

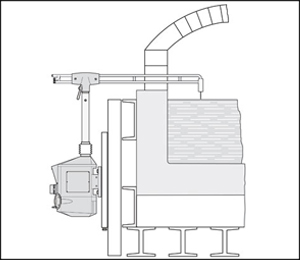

Level measurement with water-cooled measuring probe |

|

| |

|

| |

| |

There are two unit versions at your disposal: |

|

|

| |

| |

1. Compact unit with internal electronic, suitable for use in ambient temperatures up to 60°C. |

|

|

| |

2. A unit with the electronic accommodated in a separate housing, suitable for use in ambient temperatures up to 80°C. |

|

|

|

| |

Applicable measuring probes – both with and without water cooling – are available for different applications. |

|

|

| |

| |

Typ: SNG-PG-D 97i (internal) |

|

|

| |

| |

This version is suitable for use in maximum ambient temperatures up to 60°C. |

|

|

| |

|

| |

| |

Typ: SNG-PG-D 97e (external) |

|

|

| |

| |

Diese Version kann bis zu einer maximalen Umgebungstemperatur von 80°C eingesetzt werden. |

|

|

| |

|

|

For the recording of the measurement the probe is run periodically towards the melting surface by the micro process aided melting bath level transmitter. Before reaching the melting surface the probe drive mechanism will be stopped in a precisely defined distance. The now available numerical value will be evaluated by a processor, afterwards released via a D/A transformer and convertor for an analogical applied unity-power signal. The size of the unity-power signal 0/4-20mA is proportional to the deviation of the adjusted benchmark/set-point. The system follows the changing level in short measuring intervals. If the level of melting surface is beyond the measuring range, the total range will pass through (search run) and a notice of malfunction is released. The system is returning into normal operation, as soon as the melting surface stays again within the measuring range.

Together with the motor- and measuring gear all components are built-in an aluminium casting frame and effectively protected against blows, dust and splash water. The affected parts are stored in ball-type nipples and ball bearings and are to a large extend free of maintenance. The adjustment of the bench mark 0 to the required set value of the melt will be effected through a handwheel being easy to activate. The adjustable range is 80 mm and can be read-off on a laterally mounted scale.

A vertically induced telescopic tube is holding the clamping head for the probe, respectively the probe holder. Thus the probe is pivoting and continuously vertically variable. |

|

|

| |

|

| |

A well thought-out installation principle, used successfully for many years, makes installation simple and the measuring device can be changed simply in the case of fault. Due to the modular construction, maintenance and repair work can be performed simply and inexpensively.

A protected four-line display - together with a membrane keyboard - permits safe and reliable operation, even under the frequently extreme conditions in the glass industry and - if required - adaptation of the configuration to the relevant conditions on site.

A RS 232 interface facilitates connection to a control system. The software is designed for the PROFIBUS- DP (international standard EN 50 170) and enables communication to the automation system. For example, in special operating situations, the measuring range and other parameters can be adapted automatically to the relevant requirements.

|

|

|

| |

Technical data: SNG-PG-D 97i/e |

|

|

| |

| |

| Auxiliary power: |

100...240 VAC / 47...63 Hz

100...375 VDC

The electrical connection is made in a separate connection

and distribution unit through a multi-core connection

cable with connectors on both ends (standard accessory)

|

| Power consumption: |

36 VA /18 W |

| Measuring span: |

Standard 20 mm, changeable up to max. 50 mm |

| Standard: |

Measuring range: 10 ... -0+ ... 10 mm |

| Measuring accuracy: |

0,05 mm absolute (no mean value formation) |

| Transducer: |

|

Contactless with adjustable probe sensitivity |

|

| Measuring interval: |

approx. 8 sec. (at standard measuring range) |

| Characteristic: |

linear |

| Measuring output: |

0-20 mA/ 4-20 mA injected direct current |

| Load: |

500 Ohm |

| Interface: |

V. 24 Option TTYOption PROFIBUS-DP |

| Two-point automatic control: |

Relay make contact, floating |

| Probe pulse: |

Relay make contact, floating |

| Fault signal: |

Relay make contact, floating |

| Ambient temperature: |

Typ SNG-PG-D 97-i bis 60° C

Typ SNG-PG-D 97-e bis 80°C |

| Housing: |

|

Cast Aluminium AlSi 10 Mg |

|

| Colour: |

Antique-gray 09/90170 |

| Vertikal adjustment: |

by handwheel ± 40 mm |

| Degree of protection: |

IP 54 |

| Weight: |

approx. 25 Kg |

|

|

|

|

|

| |

|